Stainless Steel Tubes: A Reliable Choice for High-Pressure Applications In the world of industrial engineering, the selection of materials plays a crucial role in the importance of ensuring the durability, safety, and efficiency of various applications. Making the right decision in the selection of material is crucial, especially in high-pressure environments. For such demanding situations, Stainless steel pipes and tubes come into play, with stainless steel tube manufacturers in India playing a pivotal role. The Strength of Stainless Steel Tubes Stainless steel

Factors to Consider When Selecting Stainless Steel Pipes for Chemical Processing Stainless steel pipes and tubes are essential components of various industries, especially in the chemical processing industry. Their corrosion resistance properties, durability, and ability to withstand harsh environmental conditions make them an ideal choice for chemicals and fluid transportation. However, not all stainless steel pipes are the same, and selecting the right type of stainless steel seamless pipe is necessary for ensuring the safety and efficiency of chemical processing

Uses of Stainless Steel in the Oil & Gas Industry

Stainless steel has become increasingly popular in the oil & gas industry. It is an essential material due to its durability, strength, cost-effectiveness, and corrosion resistance properties. From pipelines to storage tanks and valves to pumps, it has a variety of applications. Its ability to withstand extreme temperatures and harsh environmental conditions makes it even more suitable for use in this industry. The oil & gas industry has been using

If there’s a unique aspect of a product like stainless steel – It is that its strength and utility withstand the test of time. Along with guaranteeing excellent performance, its long-term quality and functionality is what every business and project continually benefits from. Here are a few reasons why businesses should invest in : 1. Lengthy lifecycle Compared to other metals or materials, stainless steel has a longer life cycle due to its low-energy use in manufacturing process, highly recyclable quality, and other

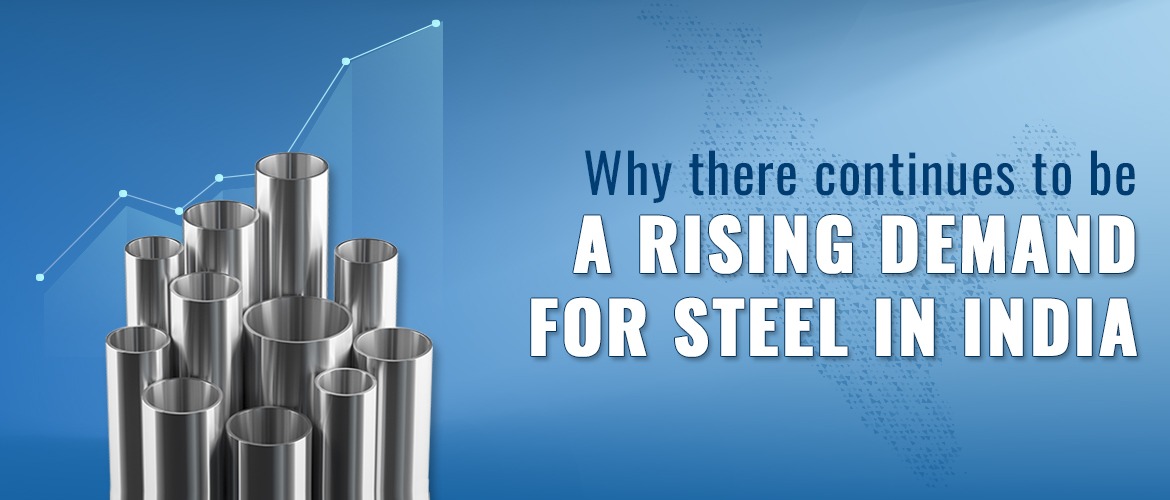

Due to its higher durability and lower maintenance, the domestic demand of stainless steel pipes & tubes continues to grow. A recent report also suggested how the rise in demand can be attributed to its increasing adoption in railways, which also happens to be a goal for government infrastructure spending. Here are a few reasons why this metal continues to be popular and widely used: Strength & Durability Ever wonder why stainless steel gets repurposed so many times for different reasons and usage? It’s because

As a stainless steel pipes manufacturer, our real strength lies in guaranteeing quality control. At Shubhlaxmi, our manufacturing process swears by few procedures products undergo before reaching your business. Here are five key steps/procedures stainless steel tube manufacturers in India can consider for quality control: Mechanical Testing: This standard testing procedure covers tensile strength, namely tension, bend, hardness and impact.

At Shubhlaxmi, we aim to offer knowledge on the various applications, uses or benefits of stainless steel pipes for growing businesses. As a stainless steel pipes manufacturer, our business believes that industries should have thorough information on the key differences and uses of various equipment pipes. Similarly, here are 7 major differences between Seamless and Welded Pipes: 1.Length: Due to a few obstacles in the manufacturing process, Seamless

Shubhlaxmi stainless Steel pipes are commonly used in piping systems to connect water, waste, gas, or other fluids. They are usually produced and manufactured in bulk due to being used across several industries like Petrochemical, Oil & Gas, Power Plants, Railways, Food & Dairy etc. Their continued bulk production is owing to the versatility of application spanning various sectors. At Shubhlaxmi, we believe that the use of this reliable and durable product helps build a lasting foundation for your business. Here are top

Did you know that stainless steel is a relatively young entrant to the world of material science? Harry Brearley of Sheffield, UK discovered ‘rustless steel’ when he added chromium to molten iron. His goal was to create a metal that does not rust. And his discovery came to be known as stainless steel. The year was 1913. Fast-forward 110 years and stainless steel has entered almost every facet of our lives. Look around you and you will notice plenty of things

You are probably aware that the term “stainless steel” doesn’t refer to one particular alloy but a group of iron-based alloys that contain at least a minimum of 10.5% chromium. Other elements are often added and the chromium content boosted to increase the metal’s heat-resisting and corrosion resistance properties. This helps to improve the metal’s mechanical properties and fabrication characteristics. Today, there are dozens of grades used to highlight the different variations available with stainless steel. These grades are universally recognised

- 1

- 2